A Midwest power utility customer was experiencing increased vibration after a refurbished Condensate pump was reinstalled on-site. They reached out to Hydro Reliability Services to help troubleshoot the vibration issue and determine if it was a problem inherent to the equipment or the result of the refurbishment. Continue reading

Tag Archives: reliability

Analysis & Engineering Upgrades Solve Ring Section Pump Failure

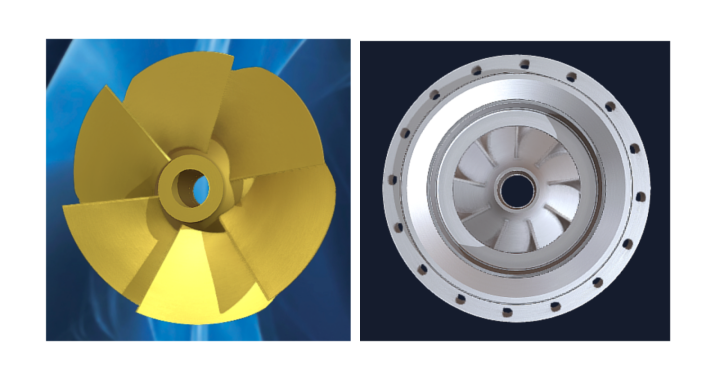

A major power plant in the United States experienced high vibration and recirculation issues with several ring section (BB4) boiler feed pumps, resulting in multiple catastrophic failures and unplanned outages. This case study details one of the pumps that was shipped to an aftermarket pump service center for a full analysis, troubleshooting, repair plan, rebuild and performance testing.

In combined-cycle plants, the demand for robust, yet expensive, barrel pumps diminished as the industry moved toward less expensive segmental rings pumps. Due to the recent shifts in the power industry, operators often face a shorter mean time between repair (MTBR), internal wear and high vibration issues on newly installed units.

After experiencing numerous boiler feed pump performance and reliability issues at their power plant, the plant owner opted to pursue a comprehensive root cause analysis and repair plan with an aftermarket pump service center in Los Angeles, California. The investigation ultimately revealed a series of underlying issues linked to the performance problems and unexpected pump failures.

Video: https://vimeo.com/452266877

Source: https://www.pumpsandsystems.com/analysis-engineering-upgrades-solve-ring-section-pump-failure

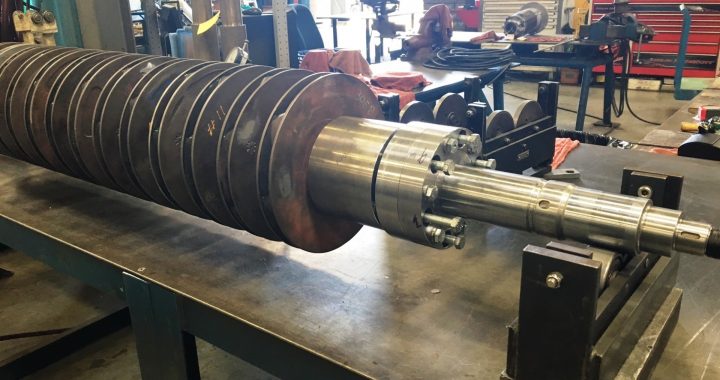

Re-engineering System Reliability

A US fertilizer plant was experiencing recurring reliability problems with its horizontal multistage boiler feed pumps. The series of repeat failures motivated the owner plant to consult with a widely-known unbiased aftermarket pump service provider. Previous experience with this company’s Texas facility gave the plant confidence that they had the capability to troubleshoot the problem and provide a solution. This type of supplier has been classified as a “CPRS”— Competent Pump Repair Shop, because their worldwide affiliates are staffed by specialists who have the fullest support of pump engineers at the company headquarters.

The aftermarket pump service provider performed a failure modes and effects analysis (FMEA) that took into consideration historical failure information and included an independent engineering analysis of the operating conditions. A review of the system history uncovered that the fertilizer plant had originally been designed with two 100% pumps. When the system was uprated, increased output requirements necessitated that both pumps operate in parallel to meet the new demand. Based on this information, the FMEA determined that the most probable failure mechanism was discharge recirculation caused by low flow operation.

Unearthing the Root Cause of Vibration Issues

A recently constructed fertilizer plant was experiencing significant vibration problems on their brand new UAN Solution pumps. This vibration forced the plant to take the equipment out of service.

The site was unable to diagnose the root cause of this problem on their own and the unreliability and resulting unavailability of this critical equipment was causing significant stress on the new plant. They heard through another fertilizer plant that a global aftermarket pump service provider had been able to diagnose and remediate their pump problems with great success. The site reached out to this aftermarket pump service provider to help identify the issue and provide solutions.

The pump was shipped to the aftermarket pump service provider’s Chicago repair shop to perform a thorough disassembly, cleaning, and inspection (DCI). The service provider’s engineering team reviewed the original pump design and historical vibration information provided by the plant. Between this review and the DCI results, sufficient evidence was gathered to perform a root cause analysis (RCA) that explained the aberrant behavior of the problem pumps. The pumps were then re-engineered to eliminate the diagnosed problem and provide the plant with reliable operation. Continue reading