Read Hydro’s brief article at the Empowering Pumps website which discusses some of the effects of operating pumps away from their best efficiency point.

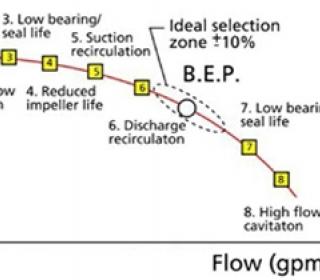

Written by Bob Jennings of HydroAire Inc., who is a Hydraulic Institute certified training instructor and pump industry veteran, the article explains the definition of BEP and the consequences of operating your pump too far to the left or right of its Best Efficiency point for a sustained period of time.

Because improving pump efficiency, increasing reliability, and extending mean-time-between-failure is a goal for most pump users, it is valuable to understand your pump’s best efficiency point. If you are not aware of your pump’s BEP for your specific application, consider testing your pump. Hydro can provide a certified performance test at our 5000HP Test Lab in Chicago, IL.