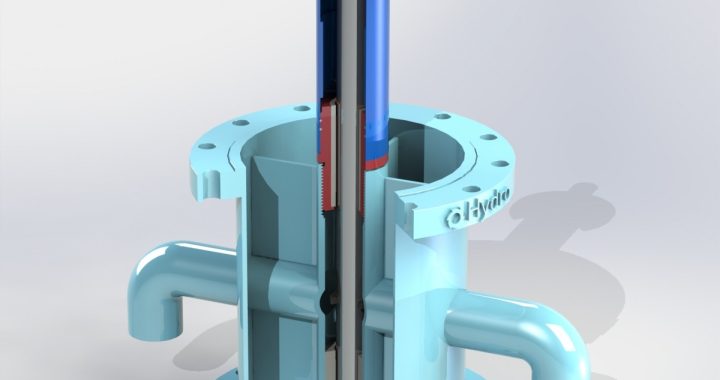

Upgrade in Action: HydroSeal

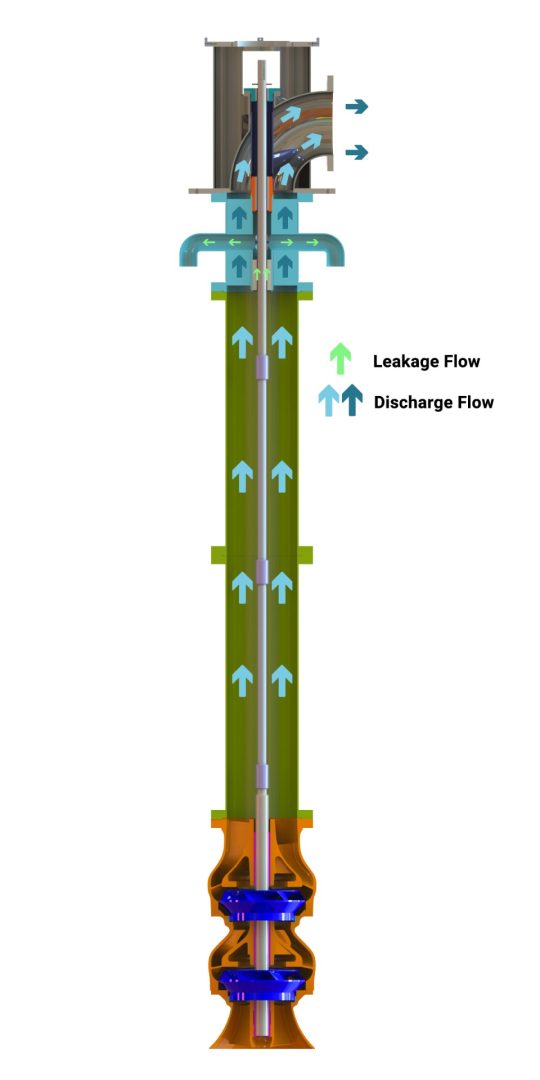

Vertical pumps have reliability and maintenance considerations unique to their design and application. One of these considerations is the pump seal design. Many vertical pumps rely on packing in lieu of mechanical seals. While it is a less sophisticated design, packing has benefits for vertical pumps, including greater ability to handle fluid with particulates, less sensitivity to misalignment, and greater stiffness and damping provided at the seal location. However, packing also has multiple disadvantages, foremost of which is the need to continuously adjust the packing gland to maintain the desired leakage rate and the requirement that some fluid must leak to the atmosphere. The cost associated with replacing worn components in the packing area is another notable drawback.

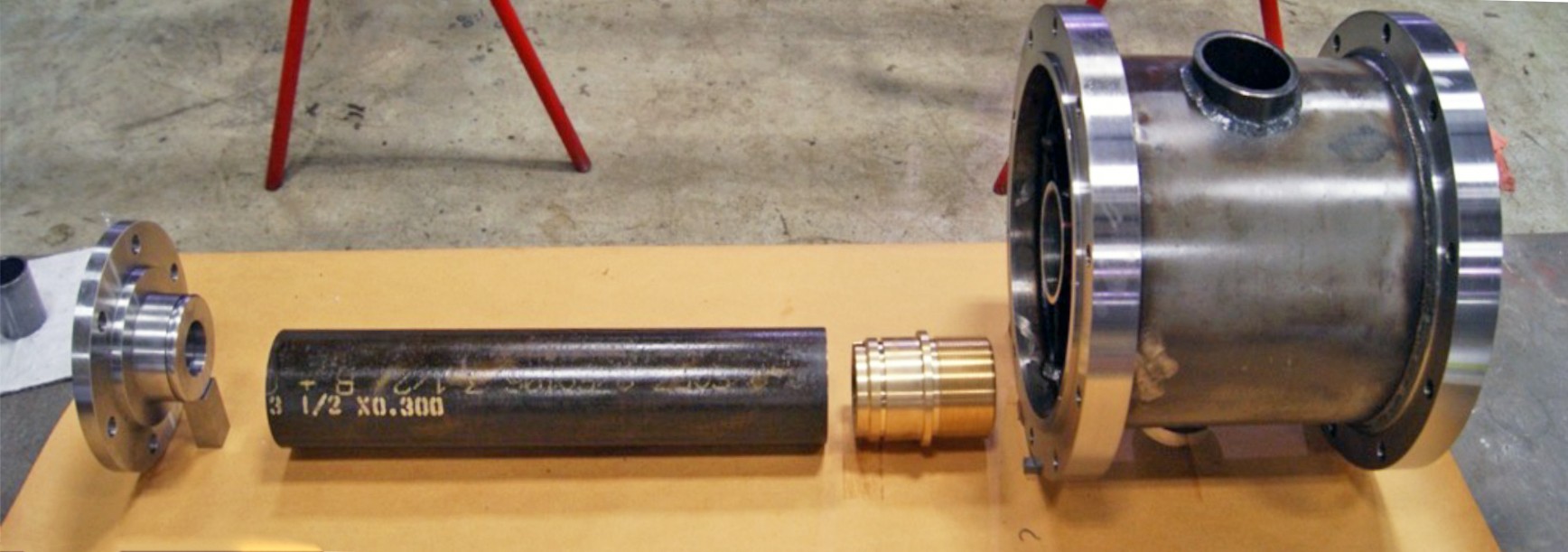

In cases where any of the disadvantages associated with packing or a mechanical seal noticeably impact reliability or the cost of operation, upgrading to a seal casing design is an attractive alternative. This is the decision that a pulp and paper mill in the Southeastern US made when experiencing reliability and environmental concerns in their River Water pump system. Faced with the need to install a new sealing device, they decided that the ability to avoid aboveground leakage and eliminate time-consuming periodic maintenance justified the investment in a vertical pump seal casing.

Read the full case study in World Pumps March/April 2024 edition.

Learn more about Hydro’s Hydro South service center and Hydro’s Engineering Services.

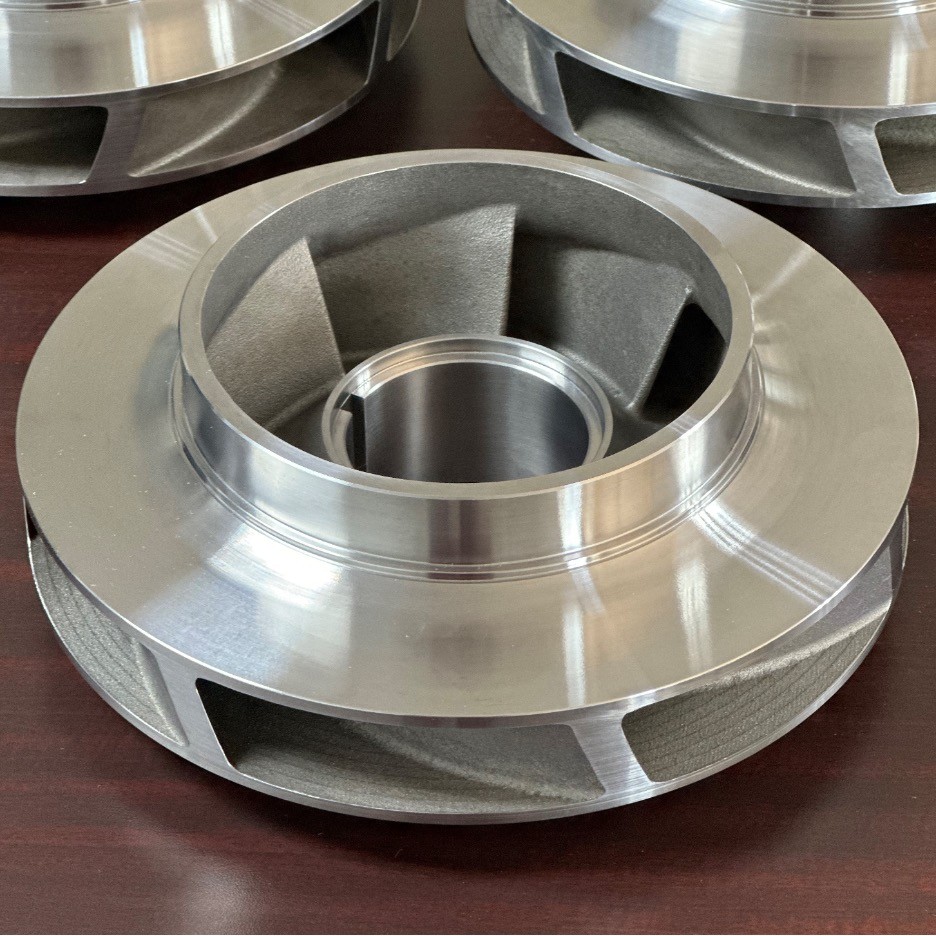

Hydro Parts Solutions recently manufactured three impellers for a rerate project being developed through Hydro’s Rocky Mountain service center in Denver, CO. Hydro Global Engineering determined the new hydraulic design for the rerated pump, which required modifications to the casing and new impellers.

Hydro Parts Solutions recently manufactured three impellers for a rerate project being developed through Hydro’s Rocky Mountain service center in Denver, CO. Hydro Global Engineering determined the new hydraulic design for the rerated pump, which required modifications to the casing and new impellers.

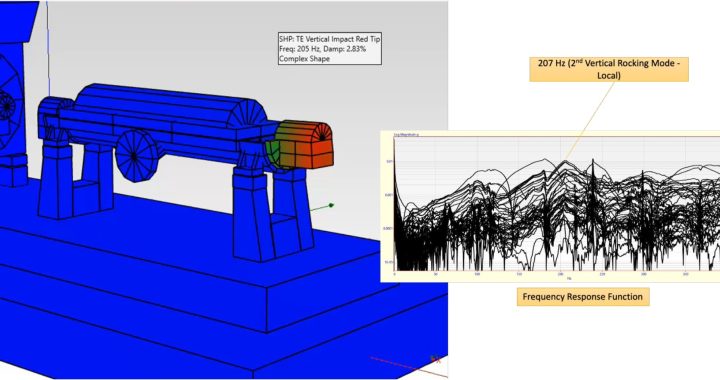

It’s important that processes are built around historical run times to anticipate needs in the short term. However, it is equally important to take a step back and ask– “is this maintenance interval really acceptable or is there something that I can do to improve it?” An end user in the Canadian oil sands industry decided to take on that challenge when faced with a problematic bitumen froth transfer pump. This end user partnered with Hydro’s Scotford facility in Alberta to develop a series of upgrades that improved operating life while simultaneously reducing the cost of repair.

It’s important that processes are built around historical run times to anticipate needs in the short term. However, it is equally important to take a step back and ask– “is this maintenance interval really acceptable or is there something that I can do to improve it?” An end user in the Canadian oil sands industry decided to take on that challenge when faced with a problematic bitumen froth transfer pump. This end user partnered with Hydro’s Scotford facility in Alberta to develop a series of upgrades that improved operating life while simultaneously reducing the cost of repair.