Custom Hydraulics for the Midstream Market

This summer, Hydro completed a hydraulic rerate project for a major US midstream pipeline. The project was completed through Hydro South, Hydro’s southeastern US service center in Alpharetta, Georgia. The project was completed with testing support from the Hydro Performance Test Lab, Hydro’s 5000 HP test facility located in Chicago, IL, with engineering direction from Hydro Global Engineering, based in Manchester, UK.

The pipeline originally used two booster pumps and the use of a Drag Reducing Agent (DRA) to achieve the desired flow rate. To increase the overall flow capacity of the line and remove the need for the DRA, the end user specified a pump to be added to the system downstream of the booster pumps.

The pump performance specifications were developed by system engineers and communicated to Hydro. The pump’s original design condition was modified to provide the necessary differential pressure required for the desired flow rate – for today and in the future. This will be achieved without the use of DRA or with little added to the system.

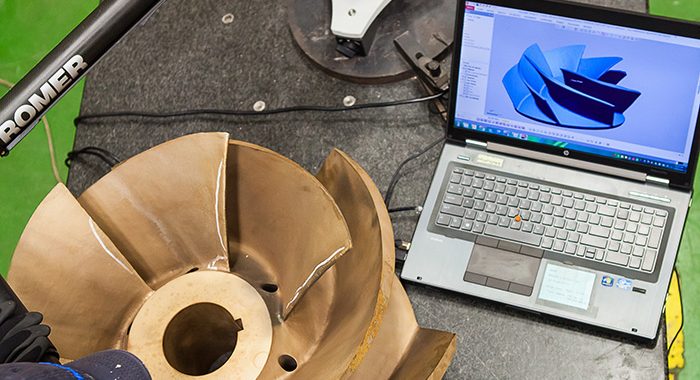

Hydro modified an existing pump casing provided by the pipeline and designed new impellers to meet the specific hydraulic performance requirements. Using computational fluid dynamics and advanced modeling, the new impellers were manufactured and installed by Hydro, then sent to Hydro’s test facility for hydraulic performance testing.

To provide an exact performance match, a larger impeller diameter size was selected for the first test and subsequently trimmed to meet performance within API 610 tolerances. Along with the hydraulic performance test, the mechanical integrity of the pump was measured with a vibration test, mechanical resonance test, and a bearing housing temperature stabilization test. All this information validates the quality of the rebuild and ensures a reliable machine.

The pipeline has a limited ‘budget’ of DRA concentration allowed pipeline wide. This concentration is measured in part per million (ppm). By adding the hydraulically rerated pump to the branch line, the DRA ppm budget can be allocated elsewhere in the pipeline. This will add efficiency and increase overall throughput.

Hydro is very fortunate to support critical industries like midstream pipelines in ensuring safe, reliable, and cost-effective pumps and rotating equipment.

Learn more about Hydro’s Performance Test Lab and Engineering Services

The Problem

The Problem